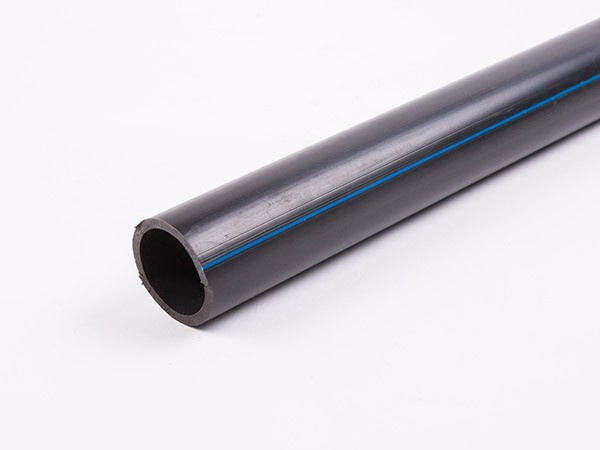

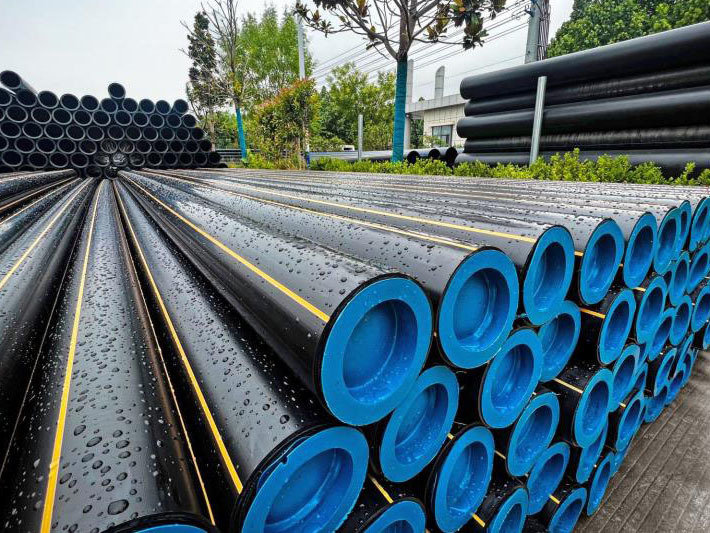

Product display

PE water supply pipe-description of PE pipe

E pipe fittings are widely used in various industries due to their stable chemical properties, and gradually replace water supply pipes such as steel pipes and cement pipes. One after another, more and more pe pipe fittings manufacturers came into being. Many customers do not know how to choose good quality pe water supply pipe manufacturers, looking forward to buying good quality and cheap pe pipes.

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

PE pipe fittings are widely used in various industries due to their stable chemical properties, and gradually replace water supply pipes such as steel pipes and cement pipes. One after another, more and more pe pipe fittings manufacturers came into being. Many customers do not know how to choose good quality pe water supply pipe manufacturers, looking forward to buying good quality and cheap pe pipes.

High-quality PE pipe manufacturers need to meet many conditions, the quality of the manufactured PE pipe needs to meet the standard requirements, and the requirements meet the following conditions:

1. Color: The color of ordinary drinking water pipes is blue or black. Black pipes should have co-extruded blue color bars, which are usually three color bars. Other aspects can be blue or black, but the pipes exposed to sunlight must be black.

2. length: ordinary PE pipe length is 6 meters, 9 meters, 12 meters, can be customized according to your needs, the length can be based on unilateral agreement. The length bias cannot exceed 0.4 percent of the length and cannot be shorter than 0.2 percent of the length. The diameter of the coil should not be less than 18 times the outer diameter of the pipe.

3. Appearance: The pipes consumed by high-quality pe pipe manufacturers have lubricated and clean inner surface, no bubbles, no clear scratches, dents, magazines and uneven colors. The pipe end cut is flat and perpendicular to the pipe axis.

4. Health function: PE pipe fittings for drinking water should conform to the relevant guidelines of the national fake standard GB/T 17219.

In recent years, with the needs of China's development to an energy-saving society, as well as the continuous improvement of people's quality of life and the enhancement of health awareness, the requirements for the quality of drinking water for domestic use are also increasing day by day. New plastic pipes have been widely used in urban water supply with their superior performance, especially high density polyethylene pipes (HDPE) with their corrosion resistance, smooth inner wall, good fluidity, no scaling, light weight and convenient installation, long service life, environmental health, low leakage advantages, get rapid development. In the course of its use, the quality of the pipe joint welding is related to the length of the service life of the pipe and whether the pipe is leaking. However, the recent news found in some places in the construction, because the construction is not in accordance with the standard operation, do not pay attention to the construction quality, there have been some water leakage accidents, resulting in some adverse effects.

Previous Page

Next Page

Previous Page

Next Page

Product inquiry