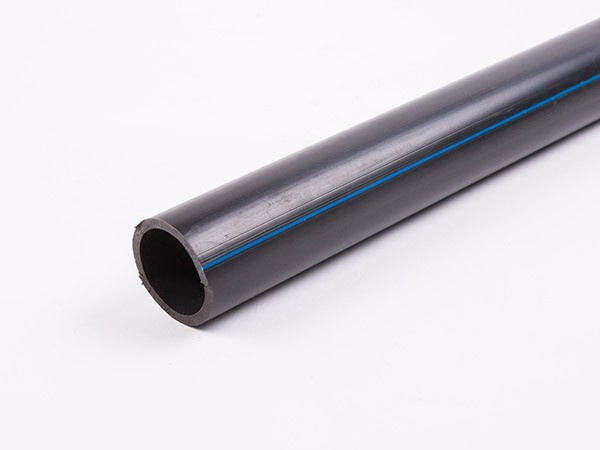

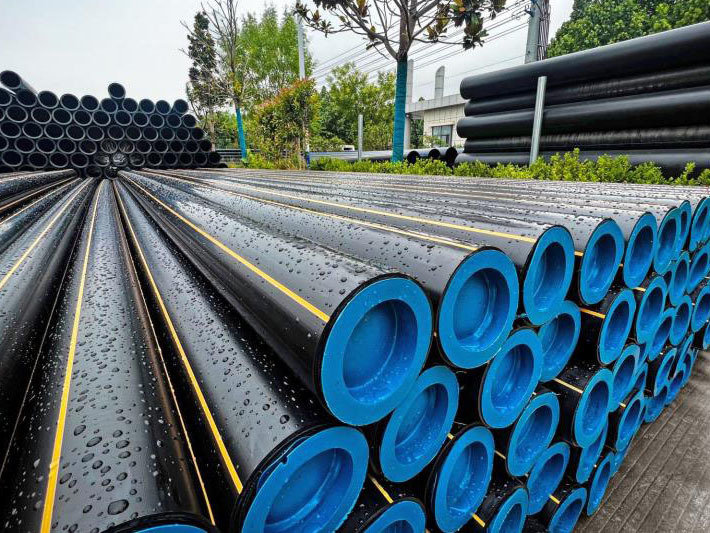

Product display

PE water supply pipe connection

Welding steps of PE water supply pipe PE water supply pipe is a special polyethylene as raw material through a plastic extruder extrusion molding, used in urban water supply network, irrigation water diversion engineering and agricultural sprinkler irrigation engineering, especially suitable for acid and alkali resistant, corrosion resistant plastic pipe environment. As the PE pipe is connected by hot melt and electric melt, the integration of the interface and the pipe is realized, and the circumferential stress and axial impact stress generated by the pressure can be effectively resisted. Moreover, the PE pipe does not add heavy metal salt stabilizer, the material does not scale, does not breed bacteria, and avoids secondary pollution of drinking water. The welding of PE water supply pipe can be divided into the following steps, which are very important. Everyone must pay attention.

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

Welding steps of PE water supply pipe PE water supply pipe is a special polyethylene as raw material through a plastic extruder extrusion molding, used in urban water supply network, irrigation water diversion engineering and agricultural sprinkler irrigation engineering, especially suitable for acid and alkali resistant, corrosion resistant plastic pipe environment. As the PE pipe is connected by hot melt and electric melt, the integration of the interface and the pipe is realized, and the circumferential stress and axial impact stress generated by the pressure can be effectively resisted. Moreover, the PE pipe does not add heavy metal salt stabilizer, the material does not scale, does not breed bacteria, and avoids secondary pollution of drinking water. The welding of PE water supply pipe can be divided into the following steps, which are very important. Everyone must pay attention to it.(1) when welding PE water supply pipes, center the axes of the two pipes, and spot weld and fix the ends of the two pipes first.(2) when welding PE water supply pipes and flange plates, insert the water supply pipes into the flange plate first, use angle ruler to find the alignment after spot welding, and then weld after leveling. The flange plate shall be welded on both sides, and the inner side shall not protrude the closing surface of the flange plate.(3) When the wall thickness of PE water supply pipe is above 5mm, the groove shall be cut to ensure full penetration. Gas welding cutting or beveling machine can be used for groove forming, but the slag and iron oxide should be removed and polished with a file until the metal light is exposed. (4) When cutting the steel pipe, the cutting surface should be perpendicular to the center line of the pipe to ensure the concentricity of the pipe after welding.(5) The flange should be perpendicular to the center line of the pipe, the surface should be parallel to each other, and the flange gasket should not protrude into the pipe, the bolt specification of the connecting flange shall be matched with the flange, and the length of the screw protruding nut shall not be greater than 1/2 of the screw diameter.(6) When welding the water supply pipe, the pipe joint shall be cleaned of floating rust, dirt and grease.(7) The flange gasket shall be selected according to the drawings and specifications. The cold water system adopts rubber gasket and the hot water system adopts asbestos rubber gasket.

Previous Page

Previous Page

Product inquiry