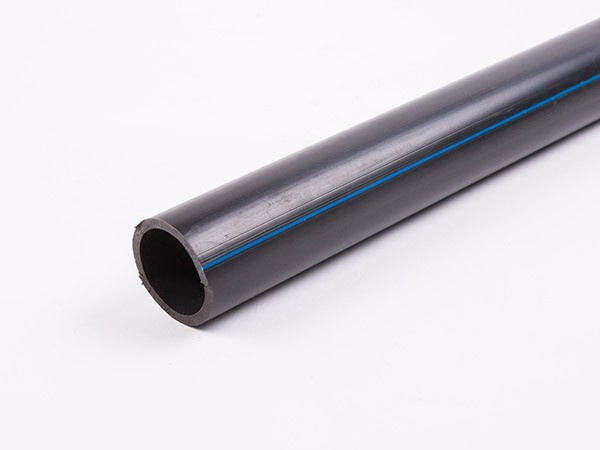

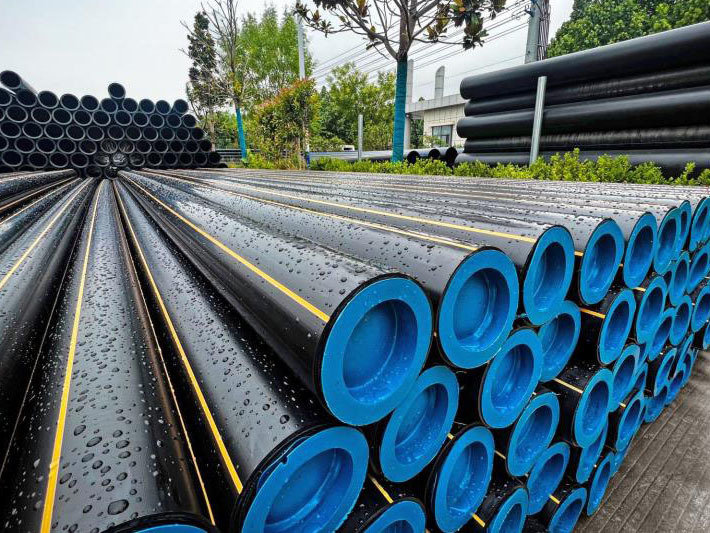

Product display

PE water supply pipe-PE pipe production

During the installation of pe pipe, the construction log must be filled in carefully every day. The contents include the temperature of the day and whether there is wind, etc. The wall thickness and pressure of the welded pipe, the model and specification of the welding machine, the temperature and voltage of the heating plate, the length of the welded pipe on the same day, several welding joints, several pipe fittings and positions, the name of the installer, etc.; In order to verify in the future.

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

In recent years, with the needs of China's development to an energy-saving society, as well as the continuous improvement of people's quality of life and the enhancement of health awareness, the requirements for the quality of drinking water for domestic use are also increasing day by day. New plastic pipes have been widely used in urban water supply with their superior performance, especially high density polyethylene pipe (HDPE)pe pipe with its corrosion resistance, smooth inner wall, good fluidity, no scaling and light weight, easy installation, long service life, environmental health, low leakage advantages, get rapid development. In the course of its use, the quality of the pipe joint welding is related to the length of the service life of the pipe and whether the pipe is leaking. However, the recent news found in some places in the construction, because the construction is not in accordance with the standard operation, do not pay attention to the construction quality, there have been some water leakage accidents, resulting in some adverse effects. To this end, the installation of polyethylene (PE) pipe is summarized.

1. attach importance to the training of pe pipe installation technicians

1. Installation technicians must be formally trained before taking up their posts.

2. Training content: basic understanding of plastic pipes, correct use of different types of installation machines, maintenance of installation machines, safe and civilized construction on site, basic procedures and precautions for welding pipes, etc.

3. The construction unit is required to have fixed trained and qualified plastic pipe welding technicians.

2. requirements during the installation of pe pipe, every day must carefully fill in the construction log. The contents include the temperature of the day and whether there is wind, etc. The wall thickness and pressure of the welded pipe, the model and specification of the welding machine, the temperature and voltage of the heating plate, the length of the welded pipe on the same day, several welding joints, several pipe fittings and positions, the name of the installer, etc.; In order to verify in the future.

3. safety construction is mainly the safety of electricity. To regularly check and maintain the installation of the machine, check whether the wire joints are wrapped in good condition; try not to construct in rainy days, so as not to cause leakage accidents due to moisture, and pay attention to prevent the installation of the machine from being damaged by rain and damp, resulting in accidents.

Previous Page

Next Page

Previous Page

Next Page

Product inquiry